Amy Congdon

Textile Designer and Biodesigner

Conducted by Ellen Enderle on April 20, 2021 at Brooklyn, New York via Zoom

Congdon has worked both in the fashion and textile industries, as well as in-house at biotech start-up Modern Meadow as Associate Director of Materials Design. In 2022, she became Chief Design Officer of Biofabricate, previously having been the Head of Design Intelligence. She has been an Associate Lecturer for the MA Material Futures course at Central Saint Martins and a visiting lecturer at other universities. Congdon's work has been featured in leading publications such as Crafts magazine, WIRED, and Vogue, and in books including Biodesign: Nature + Science + Creativity by William Myers, Biomimicry for Designers by Veronika Kapsali, and Crafting Anatomies: Archives, Dialogues, Fabrications from Bloomsbury Academic. She has exhibited in venues including the Cooper Hewitt Smithsonian Design Museum, Centre Pompidou, and the Science Gallery London.

In this interview, Cogdon discusses her creative trajectory, how she came to integrate biotechnology into her textile design practice, and how craft informs tissue engineering. She also speaks about her interdisciplinary experimental approach and her vision of the future of materials and sustainable textile design.

Interview duration: 1 hour and 14 minutes.

Amy Congdon (AC): Hi, how are you?

EE: I'm very well, thanks, and thank you so much for meeting with me. It's so nice to virtually meet you.

AC: And you, same. Meeting everyone virtually, that hopefully one day maybe we'll be able to meet in person.

EE: [laughs.] Yes, definitely. Where are you zooming from?

AC: I'm based in Brooklyn. Despite the accent. [laughs.]

EE: [laughs.] Great! Same. So close, but virtual.

AC: Exactly, I know. Hopefully, there's light at the end of the tunnel, isn't there? With all of the progress on vaccines and things opening up.

EE: It’s coming.

AC: Yeah, we’re going to get there.

EE: Well, it's a beautiful day.

AC: Isn’t it?

EE: So after, hopefully, we can go out and enjoy the day a little bit.

AC: Definitely.

EE: This is Ellen Enderle. Today's date is April 20, 2021. It is 4:02pm, and I'm conducting an interview with Dr. Amy Congdon for the Bard Graduate Center, Craft Art and Design Oral History Project, virtually, in Brooklyn. I would like to start by asking you how you identify as a maker, and how you define your creative practice?

AC: That's a really good question. I think on a very high level, I would say I identify as a textile designer—that my training is textiles. I learned how to knit, weave, print. So, all of the traditional creative training that you are given with textiles, but my path as a maker has taken an unexpected journey. One that I didn't foresee when I decided that I wanted to take a creative career path. And that was that I now work with biologists and, in particular, tissue engineers. So, the sort of practice and the title that I could give most of my work at falls under the umbrella of tissue engineered textiles. Working with tissue engineering and the intersection with traditional textile craft. During my undergraduate, I actually specialized—learning a lot of embroidery and hand techniques—things that were very, very traditional, and then ended up using those in the laboratory. It was during that journey in which I got introduced to the field of biotech. I think you could possibly call me a bio-designer: that’s a term that gets used, as well. And I got introduced to the idea that my craft skills could be used in a field like regenerative medicine or biotechnology while I was doing my undergraduate, and then it became a research obsession from there on out, really. So, I'm not sure that really answers how I identify as a maker—definitely as a craftsperson and a designer, but someone who works in interdisciplinary and multidisciplinary ways predominantly with science.

EE: That's great. Going back a little bit, I’d like to ask, when did you start thinking about and exploring creativity and making things?

AM: I think I was very lucky that the schools that I went to had pretty strong curriculums so that you were able to do that. Also, actually going way, way back, my mum has just retired and she was looking through all of the drawings that me and my brother did—I have a younger brother—and maybe it's because I'm the oldest she's like, “I don't like to think it's favoritism, I think you just did more.” So, there's a pile like this [gestures to suggest large pile], of the drawings I did and then my brother’s was like this [gestures to suggest smaller pile]. So, I think I always turned to creative outlets. I got told off once for drawing on my dad's car with a stone when I was very young!

EE: [laughs.]

AC: So, I've always been very creative and really all the way through my schooling, from when I was very young through to my upper school, and it's a bit different as I grew up and studied in the UK. We had a mix of things. My upper school had a really good art department. We had a teacher who would make canvases for us. We could stretch our own canvases. So, we were doing these huge pieces—I had an eight foot by four foot canvas when I was doing my A-levels, and I stupidly hadn't measured the inside of my little tiny car that I had and I couldn't fit them in when I'd finished. [laughs.] But also design, my school offered something called Design Technology, so you could learn woodwork, or textiles, or graphics, and things like that. So, I was quite lucky that we had good [curriculums] academically, but creatively, as well. I think I just always had the opportunity to try that when I was studying. And then as I was looking for university, I realized I kept looking at all of the courses that were the closest to art, within a sort of a non-creative, quote unquote, university. I was like, maybe I could do history of art or, or something like that, to the point where I just was like, "I feel I need to do a foundation course, which I don't know whether they do here?" I think they might be built into the programs in the States, but in the UK, it used to be common to do a foundation year, it's like a diploma, and you can try all of the different creative fields. So, you do fine art, you do graphics, you do product design, textiles, all of these different disciplines, and it allows you to try them all out and you do it full time. And then that helps you prepare for where you want to apply—to a creative college. So, I did that and then decided that textiles was what I really wanted to focus on.

EE: So, it sounds like you were a maker and a creator for a long time, high output from an early age.

AC: Yes, yes. [laughs.]

EE: And that way you got to sample a little bit and figure out what felt right. That was my next question, too, "how did you find your way to textiles and fashion design?" It sounds like it started with that kind of selection, and just kind of trying things out and getting to see what felt right?

AC: Yeah, it did. And I was very lucky to be able to try so many different things, and I love to paint and I enjoyed fine art, but I really found that I had—and of course that's a physical medium, you can be very hands-on with that—but there was just something about textiles and the affinity with something that's so close to our daily lives and, you know, we live our lives in it. It's such a huge part of our lives that I just became fascinated by the structure of things and just how stuff is made. And I realized that I thought I was more of a designer than I was a fine artist. I think I was more interested in solving problems, in coming up with different solutions, always with a very strong interest in how stuff is made. And really any piece, no matter what sort of genre or creative field it was from—if it was made really well, I was fascinated by it and I wanted to understand how it was done and then I would want to go and try it. All of this made me realize I wasn't an artist, I was definitely more of a designer and a maker.

EE: Very interesting. Did you ever deconstruct anything in those early days?

AC: Yeah, I did. I would take things apart. I also always really liked combining different techniques, so even when I was doing paintings, I would use a printmaking technique to get a design on the surface and then I would work into it. So, I was always interested in crossing things, joining things together, and "how can I go from one technique to another?" And actually for my master's, the first project they got us to do when we started was to buy, secondhand, six items of clothing and deconstruct them and reconstruct them. So, that was also a project that involved that kind of creativity.

EE: Nice. So, you were very interdisciplinary and definitely very into making right from the get-go.

AC: Definitely. Yeah.

EE: The next question, that I'm very curious about, is what prompted you to integrate a scientific approach—utilizing biotechnology—in your practice?

AC: That's a really good question. And it's actually one that—I feel very lucky—and I don't know whether everyone has this, but I definitely had a very specific moment where everything changed. And I remember it: it was my first year of my undergraduate, and I studied something called Contemporary Textile Practices. So, after my Foundation I wanted to do textiles and the reason I chose that particular course was because you didn't have to specialize. So, I don't know how it is in the States or in other countries, but in the UK, if you do textiles, you tend to do maybe like a year trying different things and then you have to choose a pathway. So, you have to choose print, knit, or weave—sometimes there's a multimedia or one where you can combine, but mostly you have to specialize. And the reason I liked the course that I chose was because you didn't have to specialize. So, we had everyone from fine artist textiles through to people doing commercial design, for [things] like print for interiors. It was a really nice mix, and I liked that because I didn't want to just get pigeonholed into working in one particular part of textiles. I kind of did in the end anyway, but my tutor—this is turning into a very long-winded story—but my tutor at the time handed me a magazine called Selvedge, which I don't know whether you have it here, but it's a lovely, fairly traditional textile magazine. I don't know whether you’ve seen it before?

EE: Yeah, I’ve seen it before. It's great.

AC: Great. It’s an amazing magazine, but not necessarily known for its cutting edge content. I think it's great, but you know, it's not necessarily where you would go to look for the latest technology and trends in textiles.

EE: Sure.

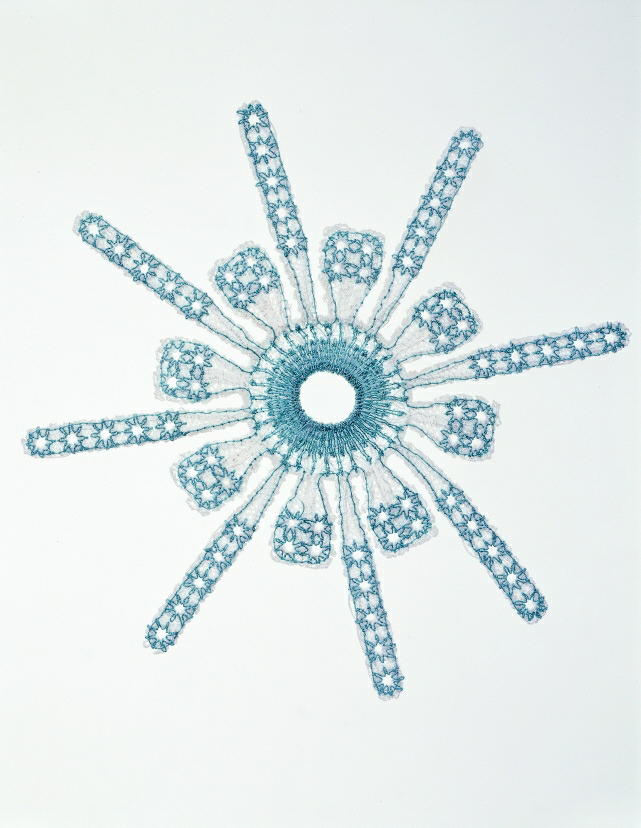

AC: But there was an article on medical textiles, and there was this piece in there called the Beautiful Snowflake, it’s nickname was the "Beautiful Snowflake." And it was a completely embroidered medical implant created for a patient who needed reconstructive surgery in their shoulder. The patient had a tumor and the surgeon needed lots of different attachment points to sew the muscle back on to this particular implant. And the reason why embroidery was used was because you can mimic natural structures in the body. With embroidery you can design it in such a way that if you cut it, it doesn't fray or unravel, which with a knit or a weave it does. It won’t stretch and expand in the same way that a knit would either. I just became fascinated by these millennial old stitches, like a running stitch or a satin stitch, being used to repair the body. So, it was this particular piece that I saw, which became a research obsession about, “how can my knowledge as a textile designer and a textile craftsperson be used in a field like regenerative medicine?” And then I became introduced to a nascent field where people were thinking, “well, why can't we grow our materials using biology?” For example, if we can grow skin for burn victims, why can't we grow leather? If we can brew beer and get bacteria to make alcohol, can we use them to spin a thread of cellulose? So, it was both the, "wow, textiles are being used in science" and then, "okay, there's all these people starting to look at, 'how could you use the tools of biotechnology to grow materials for consumer products.'" It was a very specific moment—literally reading this article and that particular piece. I think it was one of TIME’s Greatest Inventions, like twenty years ago, and it's been in the Cooper Hewitt, and venues like that. I think every single talk I've given, I have had an image of the Beautiful Snowflake in it, and all my friends that I studied with are now like, “Oh no, no, not that piece again”, but it was that influential to me. It's all that piece’s fault. [laughs.]

Beautiful Snowflake, Ellis Developments, Nottingham, UK, 2004. Photo: Ellis Developments. Courtesy of Amy Congdon.

AC: I actually ended up meeting the designer of that piece. And when I was on my masters, I had a little bit of funding, and I was looking to get the digital embroidery machine and I had met the maker of that piece and had gone on to interview him on my BA, and he was fantastic. I said, “where did you get your machine?” And he said, “well, actually I'm retiring and my wife won't let me take it home. Would you like to buy it from me? You can pay in installments.” So I actually have the machine that embroidered the Beautiful Snowflake, and that's what I did most of my embroidery on for the resulting masters and PhD work. So, yeah, that was a really incredible thing. I never expected it—ending up getting that machine, as well.

AC: Yeah it was a really lovely moment. He'd always been very fascinating—he'd been a specialist witness when textiles were involved in court cases and things like that, and he always talked about knowing the importance of understanding structure, from the fibers to the yarn, and ultimately, the textile. Understanding the structure relationship is really, really important. That stayed with me, as well. Once you understand how things break down to their component parts and you can build them back up, that's also really very much a craft way of thinking– you have to understand all your materials and all your processes, and then you are free reconfigure and to push the boundaries or to do different things because you understand the fundamentals of what you're working with. So, both that piece and its inventor were really instrumental in my research.

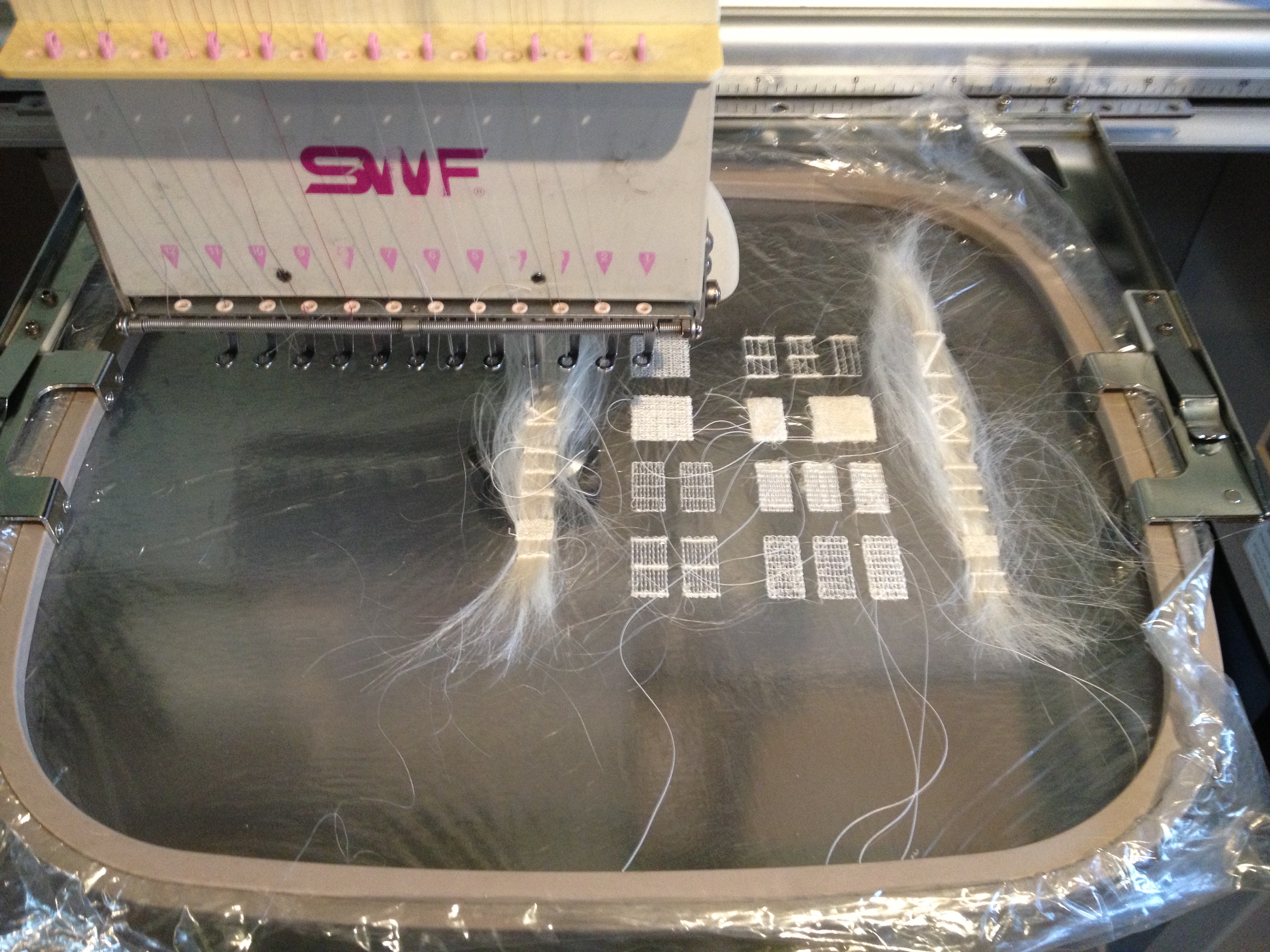

Scaffolds being digitally embroidered onto dissolvable fabric, Suffolk, UK, 2015. Photo: Amy Congdon.

EE: Sounds like it. That's wonderful. The next question that I have, you've touched on it a little bit—maybe you could expand upon it a little bit more? You studied at the Norwich School of Art and Design and the University of the Arts London, receiving your PhD in tissue engineered textiles from central Saint Martins in collaboration with the biomaterials and biophotonics department at King's College in London based in Guys Hospital. Can you talk a little bit more about what these experiences were like for you?

AC: I think for me the main thing about Norwich was that it was a really lovely traditional art school; it didn't offer anything other than creative courses. We had great workshops, and really fantastic technicians. I've taught as well, and I'm always like, “well, yes, the teachers might give you input on your project, but you want to be best friends with the technicians because they're the ones who are going to teach you the practical skills and also help you get your work done.” So we were lucky to have the people we had there. The main thing for me was being somewhere where I didn't have to specialize. So, I was free to explore textiles really, really broadly. And also, it was great to be part of a cohort which was really diverse, as well. For example, one of my friend's final pieces was working with charcoal—thinking about charcoal as a textile, and lining walls and working on installation pieces, through to someone who was doing these beautiful caricature prints for children's interiors. It was interesting to see everyone's different approaches to textiles as a medium. Through that process, I had become fascinated by the science side of things, and with constructed textiles. How you make things, their structure, and creating, and using techniques in ways that maybe weren't so usual. So, I was producing these structural pieces that were reinforced with embroidery and things like that. I knew once I graduated there that I wasn't ready to go and work in a design team anywhere. And so I decided I wanted to go and do a masters, and I read the core synopsis of, it was originally called Textile Futures when I did it, but it's called MA Material Futures now—and it was looking at the future of materiality from the perspective of craft, science, and design. So, I went and did that, and that was—whilst I totally appreciate it's a really difficult thing, more and more so financially, to be able to continue to study—it was really an amazing experience because I was with a whole group of people who were looking at what was next for textiles and design. It was a great experience, helping me to further decide what it was I was really interested in, what I wanted to do, and just to further research. I think I also never really realized that you could make research a career, I know that's changed now, but definitely when I was studying in a creative undergraduate program I didn't really know that you could make research a career.

EE: Sure.

AC: And that’s one of the things I loved the most. I'm just fascinated by, and curious, about things. So, I did that master's and it was, again, incredible—people looking at everything from, "how can the subconscious mind affect textiles?" through to "can water be a textile?" or looking at dyeing textiles with different soil samples from around the world—really, really far reaching. It was a great mix of people and tutors. We were introduced to everything from architects to doing a project with Microsoft. It was incredibly diverse, which I think helped because it developed your approach as a designer and a maker even further. So while I was on that course, the professor who ran the program said, “I think you should consider doing a PhD,” and my reaction was “no, I don't want to do a PhD. I've been studying since I was like, three.” Well, I don’t know about three, but you know, I'd been in school since I was around five and I thought you know, "I'm good!"

EE: [laughs.]

AC: But I went in to do a residency between—I literally graduated in June and left in July, and did a three month residency at somewhere called SymbioticA in Western Australia, in Perth. It’s an arts department within a science department in a university there, and it's run by Oron Catts and Ionat Zurr, who are collectively known creatively as the Tissue Culture and Arts Project. SymbioticA is a program where you can propose a project and you can go and work with scientists and actually get your hands dirty working in the lab. And up until that point I'd been researching, what does science mean for design? But I hadn't been able to get into a lab—unsurprisingly, no one wants to let, you know, an undergraduate student with no science training into their lab. So, I went there and I took all of these different textiles that I had created and I learned to do tissue culture. I was seeding cells onto textile scaffolds, and just understanding how to do that. All of that experience led me to decide, “okay, I think it's time. I do actually think I should do a PhD,” because there wasn't an industry that I could go and work in, but I felt very strongly that this was the future of, or was going to be a big part the future of, how we make things. So, I applied and ended up doing the PhD part-time. It was based at Central Saint Martins in London, which is where I did my masters. To compliment the creative institution I found an incredible professor of tissue engineering at Kings College London in the department of Biophotonics and Biomaterials, based at Guy's Hospital. The scientist I worked with who was a supervisor on my PhD, Professor di Silvio, her father used to be a bespoke tailor on Savile Row. So, it was a lovely connection, and she had a fascination with fashion and how stuff is made. She got this random sort of reach out from somebody studying a PhD in creative college saying, “can I come and speak to you? I'd love to work in your lab.” And then I showed her the research I'd done, and she let me come and work in her lab as a non-award student, allowing me to run experiments. She was always just incredibly supportive. To begin with the PhD was looking critically, and conceptually, what it meant to grow materials for fashion and for textiles. But very quickly, because I'd been introduced to working in the lab, the focus of the research became ‘how can my skills as a textile designer have impact in tissue engineering”? I wanted to know what was possible now and what my training could bring to the table. That's ultimately what the PhD became about, it was doing all of my own lab work and treating it very much like any other craft skill that I needed to develop. When I was working in a lab the cells were my raw materials.

EE: So, that hands-on experience at SymbioticA was the start of really you getting into a whole new venture, and then this making and your research—really innovative research—were just kind of side by side.

AC: Yes, definitely.

EE: That’s great.

AC: And it was, it really helped having had that experience of knowing that I had training. It also helped me get my foot in the door because they weren't letting someone loose that could have, you know, infected everyone else's experiments—someone who doesn't know what they're doing. It was a great introduction. And I went thinking, “I'm going to just grow these huge pieces of skin and leather and that's going to be really easy, ” and then I realized just how complicated it was. And the timelines involved in that kind of scientific complexity, but it was great. I think you can tell people stuff, but until you go and do it and try it yourself, it's such a different experience. And, I'm a really strong believer in my tacit knowledge. For example you can give everyone the same recipe, but you’re going to get a different cake at the end of it because there's certain things that you just have to learn by doing. And it's knowledge in your hands that you can't pass on until someone has tried it. I was only at SymbioticA for three months, but it was a really intensive three months and it definitely helped set me up for the rest of my research and PhD.

EE: Great. That's fantastic—such a wonderful backstory on that. You learned so much so quickly.

AC: [laughs.]

EE: So, from the academic to the professional: I'd love to know about what some of your favorite projects have been, that you've been able to work on in your career so far?

AC: That’s a really good question. It's not something that I’m used to, it's nice to be asked to reflect back. I think a favorite thing that was part of the PhD, but that helped inform my professional career, was that I was doing all of this stuff with the PhD and I was making all of these scaffolds and nothing was quite working. And I realized I'd tried to become a tissue engineer and I had to remind myself, “there's plenty of people who are tissue engineers, and they've got PhDs in it. And I'm never going to compete with them like that.” I needed to go back to what it is that I do, and I realized I didn't understand the materials I was working with. So, I took it right back to basics, I was like, “I'm going to just screen a bunch of fibers from across the textile spectrum and see which ones cells will attach to and which they won't.” With that approach I ended up building a materials archive and really trying to understand what were good materials and what weren't. And we actually discovered a material that we can’t find any research done with it in tissue engineering up until this point, so that was really exciting. During that part of the research I started understanding that the scale was hugely important. So rather than a cell attaching at the yarn scale, it actually attaches to the fiber scale because you want something that is comparable in terms of size. So, it's a bit like saying, the only way I can describe it is, if someone has a mattress to lie on, they could just starfish, but if you give them a long thin beam they're going to lie in a very specific way.

EE: Yeah.

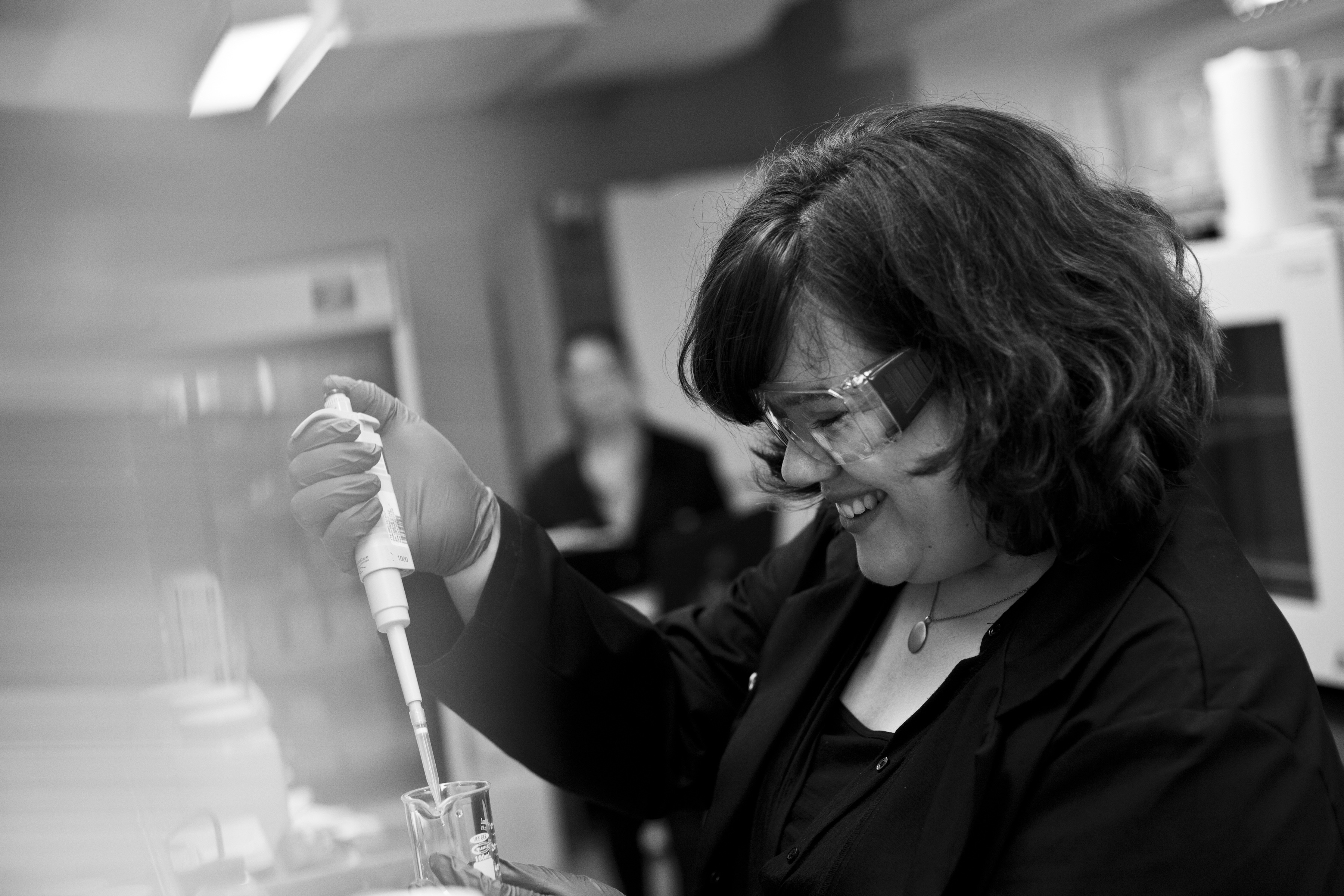

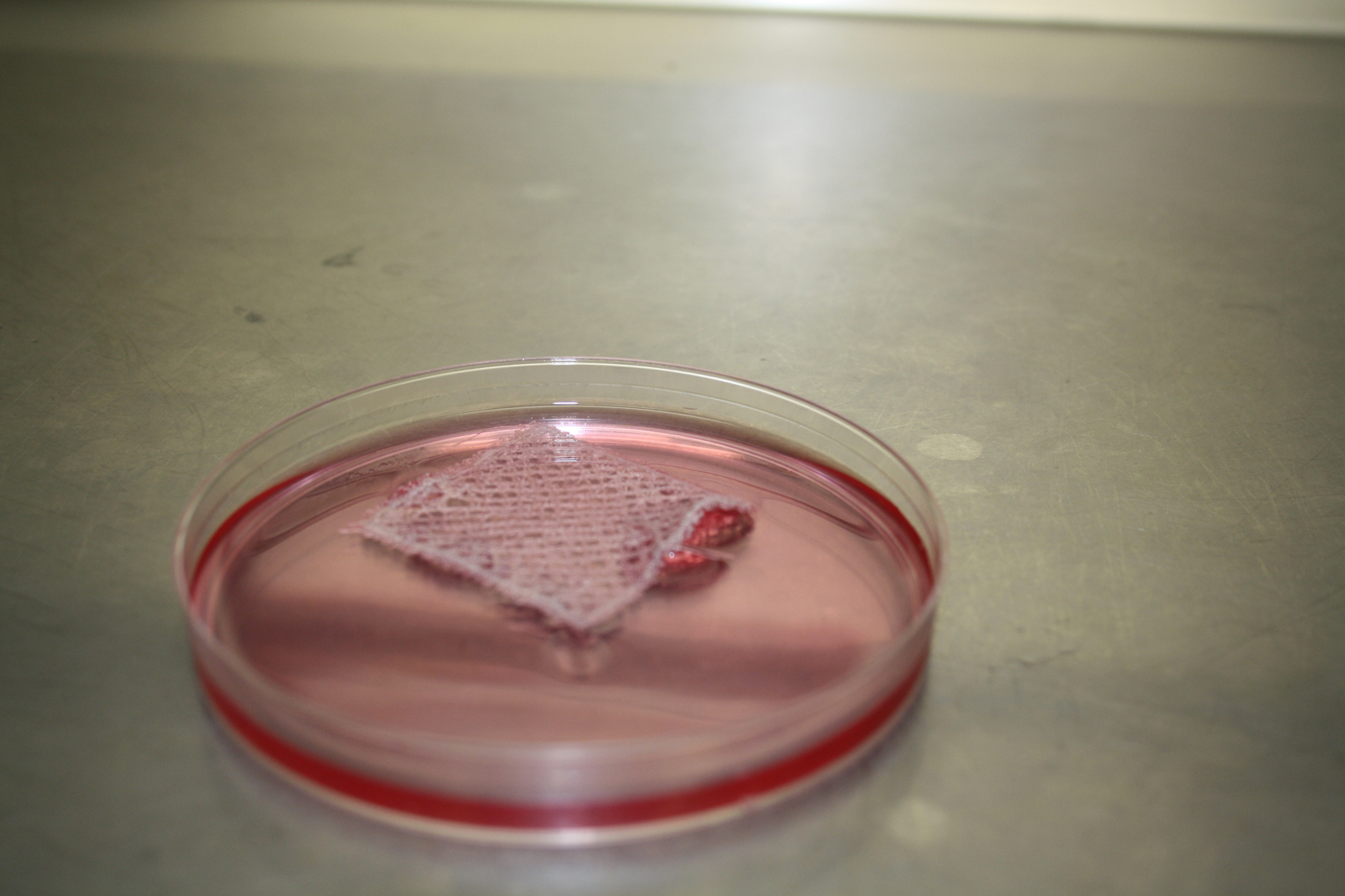

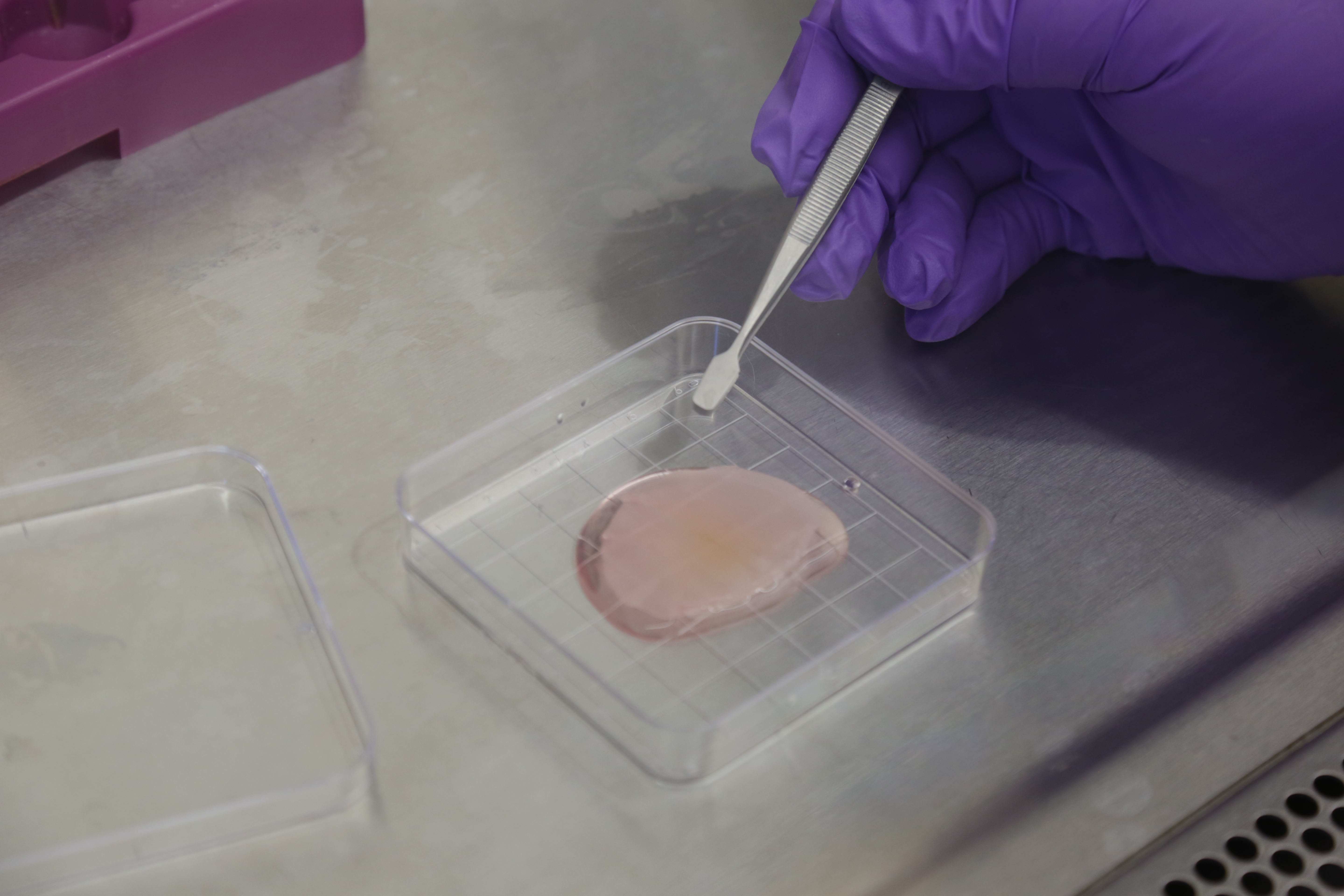

Top: Embroidery onto a cell strainer, London, UK, 2016. Bottom: Seeding a scaffold in the hood, London, UK, 2016. Photos: Ann-Kristin Abel.

EE: Sure.

AC: I was very, very lucky, but essentially it meant that I could start developing scaffolds for multiple different applications. Which ended up being the final work for the PhD—the material archive and the scaffolds that I made. That was a really important project for me, because I took a step back and realized I needed to lean into what my skill set and knowledge base was and how to use that, and think about what did that bring to the table? That's what I've taken into a professional career—that when you're in a multidisciplinary team you want to be comfortable to try things in a different way, and you shouldn't be rigid saying “this is the way I've been taught, so that's the way we've got to do it.” You want to be comfortable to try different things, but you should make sure you know what you're bringing to the table and knowledge base, because how you work and the way you approach things is very unique to you and your practice. So, you should lean on that as a starting point, and then feel comfortable to explore different things.

Anne May Abel, specially designed and produced tweezers for working with textiles in the lab, holding an embroidered scaffold, London, UK, 2015. Photo: Amy Congdon.

EE: That’s great. So, you lean into your strengths, and then also stay open to and excited about experimenting and pioneering in new ways. I'm curious what you're working on currently?

AC: I finished my PhD, it ended up taking me eight years because I was working on it part-time, and working at a start-up for part of it! I passed my viva mid-August of last year [2020], and a lot of the time the last few years was focused on writing up. I rather stubbornly thought—that won't take long working full-time at a startup and writing up a PhD! [laughs.] You know, that should be pretty quick!

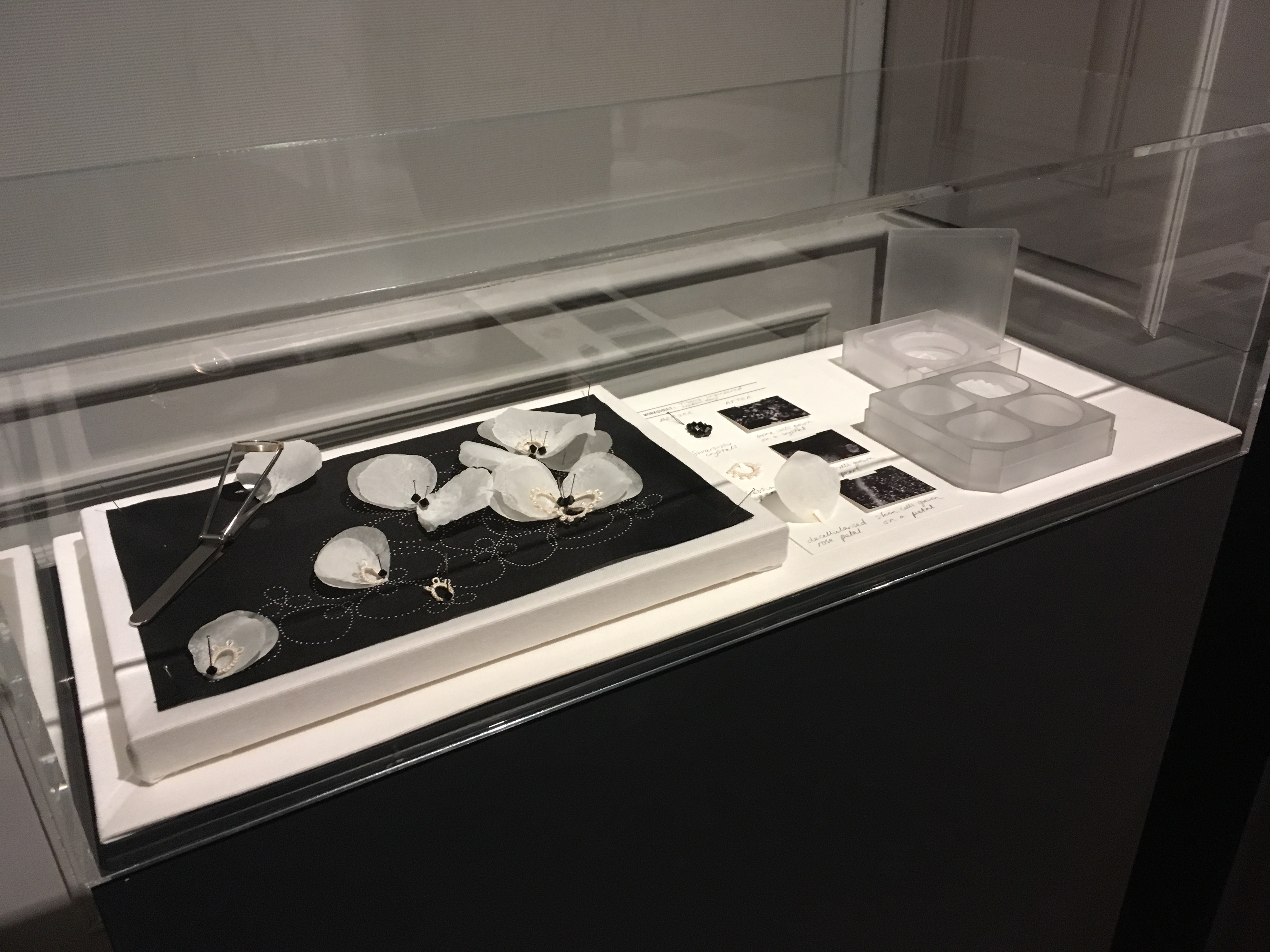

Tissue Engineered Couture on display as part of the exhibition Nature—Cooper Hewitt Design Triennial at the Cooper Hewitt Smithsonian Design Museum, New York, New York, 2020. Photo: Amy Congdon.

Seeding a decellularized rose petal for the Tissue Engineered Couture exhibit, New York, New York, 2019. Photo: Ali Schachtschneider.

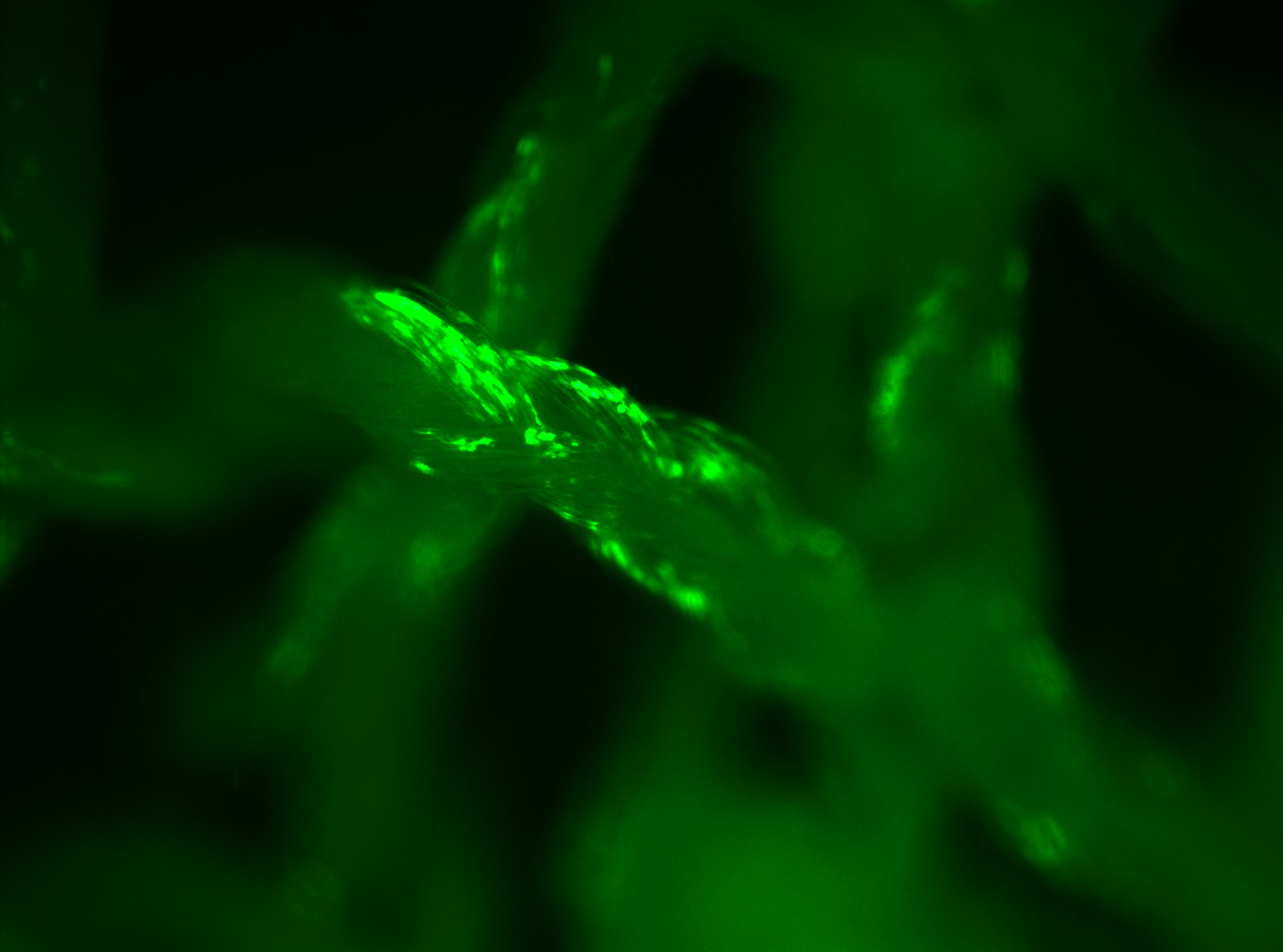

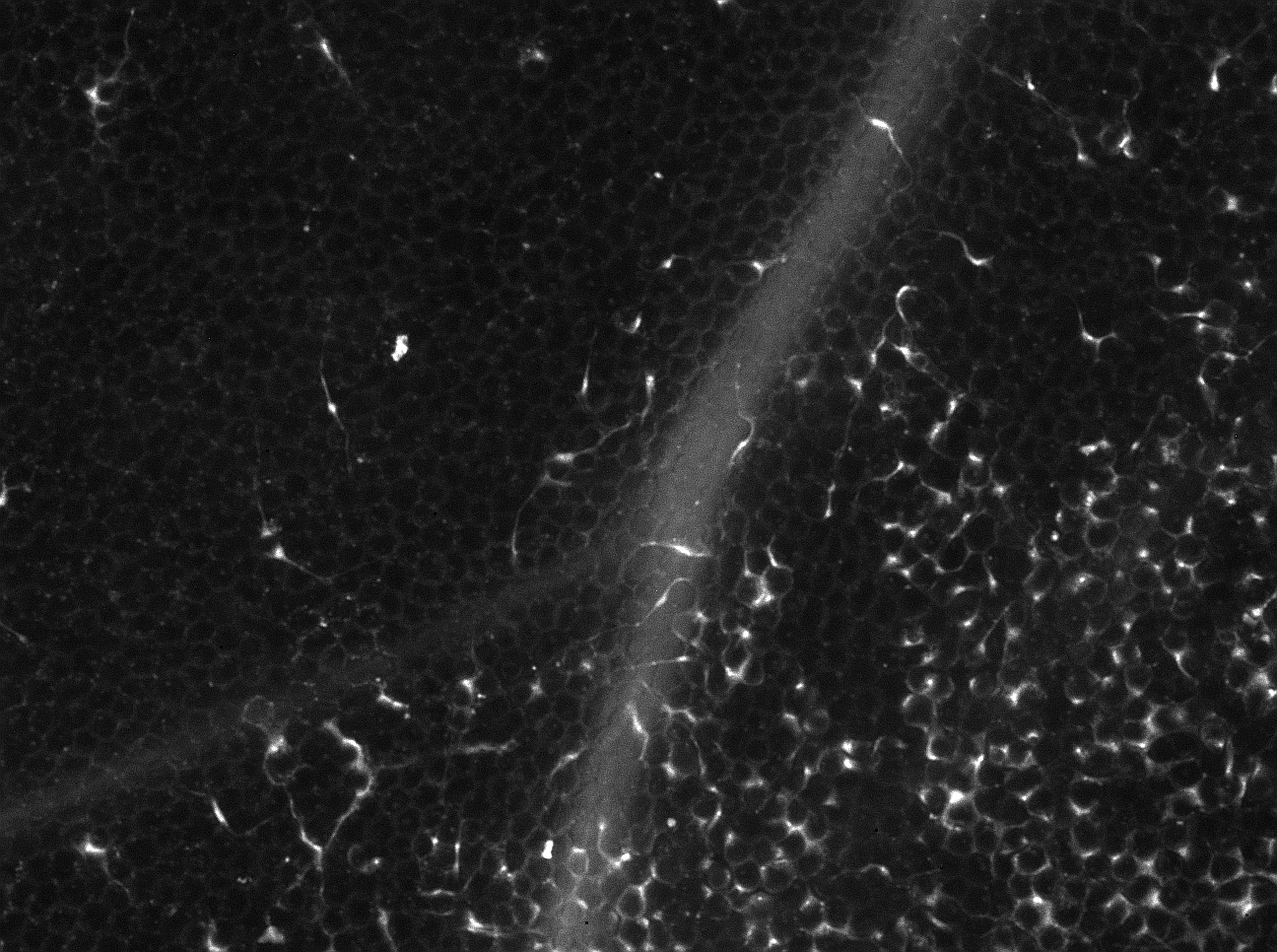

Skin cells on a rose petal under the microscope for the Tissue Engineered Couture exhibit New York, New York, 2019. Photo: Amy Congdon.

AC: Yeah.

EE: Understandably.

AC: A bit of a long-winded answer to "not much practically right now."

EE: But it’s all so fascinating. I did want to ask about the Cooper Hewitt exhibit—what was exhibiting like for you?

AC: It was amazing. I mean, that exhibit and the people who were in that one—to be asked was a really incredible honor. And it was one of several exhibits, around the same time, focusing on nature and biotechnology as a theme. The Cooper Hewitt show was really beautiful—especially how they sectioned it up. For example, designing with nature, or through nature, and the people that were in the show—it was such an honor to be included in that cohort. The piece I exhibited was developed especially for the show, and it was actually a show that was also shown in the Netherlands. I always find it's good to have a deadline and something to make work for, because often when I was working in the lab, you'd make something and then you'd stop the experiment and you might get a slide with a piece of thread on it or something like that, but most of the stuff I was working on you couldn't see with the naked eye and you could just keep researching and researching and researching. So, it's quite nice to have a point in time where you have to make something. I think, "okay, how does it manifest into something physical?" That was, for me, the work, thinking about "how does the research fit into both the biomedical and regenerative medicine field, but also into future fashion?" For tissue engineering, specifically couture, because it's expensive and it's time consuming. There are some people looking at it for replacement leathers, but that is a tricky thing to make work on a commercial scale. In the case of Cooper Hewitt it was great to make that piece and think about what my relationship and my reaction to the theme of nature is. I ended up combining a couple of different projects, or techniques from a couple of projects that I'd previously done as part of the PhD. I had previously taken the tissue engineering technique, decellularization, out of the lab and used it in the design studio. In the case of the PhD research I was decellularizing bacon—it was called Haute Bacon. But then, using that and treating that with lots of textile techniques—I was dyeing it, printing on it, laser cutting, things like that, but you just strip all of the cells away and you're just left with the extracellular matrix: you're left with the collagen, elastin, and the structure of the material without any of the cells on it. So, I took that technique, but used it with rose petals and then was using tissue engineering techniques where I was seeding skin cells back onto those scaffolds and trying to grow skin cells on the petals. That’s what the project ended up being. And it was a really fascinating process to develop the piece.

EE: Sounds incredible. It's so interesting. If you'd like to comment any more on what your process is like? It sounds like you're working in the lab quite often.

AC: Yeah, definitely. The biggest adjustment, I would say for me as a designer is getting used to working in a lab environment. I think the last time I studied science was when I was maybe like sixteen or seventeen at school. It's definitely something that, I think, either you enjoy it, or it's not for you. Most people tend to have one of those two reactions to it. What I would tend to do, especially when I’m developing scaffolds, is I will work in a studio with different materials, making various structures, and that will be something that I do by hand a lot of the time. And the reason I use hand techniques is because you can be very intuitive and very quick, so you have ultimate control over what you're making, and then you only need to make one or two, whereas if you're using a more industrial process, you end up having to make a lot more. You have ultimate control if you're making it so by hand. Then the scaffolds would go and be sterilized, because when you're working with cells they don't have their own immune system, so you have to make sure everything is sterile. Working in a lab is a bit like that game of, I don't know if you have it here, like Operation, where you can't touch anything because otherwise it's going to you know—

EE: That horrible noise happens. [laughs.]

AC: Exactly. [laughs.] And you get very good at doing that. So I would sterilize everything and then when you’re working with the cells, and you have to grow up a certain number. It's a different mentality as well, when you're working in the textile studio you can essentially leave anything out for, you know, for weeks, months on end. Whereas when you're working in a lab, you have to be very cognizant that what you’re working with is living.

EE: Sure.

AC: And you have to look after it. You can't disappear off for a week or two, otherwise, you're not going to have any materials to work with when you get back. Additionally, it is interesting when you're working because you have to work in a hood which is sterile, and you’re wearing gloves. So coming from a discipline where it's very tactile and you're used to touching everything, you can't touch anything with your hands because of sterility. You're always working with a tool, that might be tweezers or a pipette. Your experience of working with the materials is mediated by something else, which is quite a change from working in the studio. Then often what you're working on in the initial stages you can't see with the naked eye. You're having to look down a microscope to see it. That's fascinating as well. I even had points where I said, "okay, but how big is a cell?" I was like, "that sounds like the most basic stupid question," but, "how big is it? And how big is it in relation to what I'm working with?" Because I couldn't wrap my head around it. But once I understood the scale, then that helps you to build up an understanding of everything else. But yeah, working in a lab is a very different environment to working in a creative studio. And you have to learn a lot of patience very quickly. You also learn that we've gotten very good at predicting and working with biology, it's still a living medium, so there are no guarantees that something is going to work. You just have to give it time and patience! It makes you flex other parts of your creative muscle. But even when you're working in a hood and it's mediated by tools, there's a craft in working in a lab and in doing tissue culture where the better you are at it, I think, the better the results. You're less likely to get any infections, for example. There are specific hand movements you perfect in working with cells for example you use an enzyme to get them to lift off the bottom of the culture dish. How you rock that dish to get them to separate, or how you break up the clumps varies from person to person– there's a lot of hand movement involved. I think people tend to present science as very linear. For example, we wanted to find out if x is true, so we did this, this, and this. And we found it was either true or false. This is reinforced by the way protocols are written—they’re very straight and set. But there's a lot of tricks that you find that you wouldn't know unless you've done it. So, I think there's a lot of creativity and a lot of craft involved in doing the lab work, which you don't see until you work in that environment yourself.

EE: It sounds like there's a certain artfulness to it, as well.

AC: Yeah, definitely

EE: That you've mastered.

AC: Well I don’t know about mastered! But it’s really fascinating, the choreography of "you go from here and here," and knowing instinctively what's the most efficient way of doing it.

EE: Yeah, that's great. My next question for you is, do you have a design philosophy or ethos?

AC: That's a good question. I think it must be really the importance of doing, and trying, and getting hands-on. That has always been the thing I've lent on throughout my creative career and practice—I understand best by doing. It's how I process information. So I’d say that’s definitely my ethos—which is to learn by doing. You have a better understanding in that way. And then I think, in terms of a philosophy or a statement that resonates with me is the vision statement we have as Biofabricate: a sustainable material world, built with biology, not oil. And I think the idea of building with biology and learning from nature and doing it in a way that is additive, rather than subtractive or extractive is an important driver for me as a designer. We need to learn from nature, which builds in ambient conditions with no waste. How do we take that as an approach to design—making in a world where we're still doing it the same way we did from the Industrial Revolution, the "heat, beat, and treat" way of making. Nature has had a long time to perfect how it makes things. I mean, it can make anything from giant sequoia trees to the most beautiful, tiny intricately made propeller, which is at the nanoscale and is something that we can't possibly dream to make by any kind engineering skills we currently possess. So, it’s a great teacher and a great source of inspiration.

EE: The finest art, the finest artist, nature. Yeah. That's an amazing ethos and philosophy to have, very admirable. Next, I’d love to know what makes a great design for you?

AC: Another really good question. I think I would subscribe to less is more and the simpler something is the better. I always think good design is where you have a range of rules or parameters, and you've been really creative within that. But I also think I like things that are beautifully functional, I don't think that it's ever good to over complicate things. I think it's Dieter Rams that said, “good design is as little design possible.” Good design is design that you almost don't notice. I think it's when something looks effortless, it's often anything, but. But good design is something that looks effortless, and works really beautifully.

EE: What are some challenges you face in your field or potentially will face in the future?

AC: These are such great questions. Timelines have always been a challenge in this field. As well as the high performance requirements we’ve come to expect of materials. The majority of innovators in this space are going to be, or are launching, in the fashion textile space, because it is one of—I say easy, and I don't mean that in a derogatory way at all—is it easier than others in terms of, perhaps, performance, and there's potentially a little bit of leeway, particularly on the luxury end, for some amount of higher pricing in the short term. Although that's very difficult, and of course the majority of fashion is used to very cheap materials. Even though fashion is one of the first sectors that biofabricated or biomaterials are going to show up in, there's a real mismatch between the timelines of fashion, which where they’re like, "I can have it with my next collection" or "I can't have in six months?" Whereas the timelines biology are measured in decades sometimes. So that's a challenge. I also think it's a challenge, when we look at the materials that we've gotten used to and the fact that they have incredible performance. When you look at the world of synthetics and what they can do—the stretch, the comfort, and the fact they’re cheap—that it is a huge bar for any new material to try and meet that, let alone exceed. And a lot of brands are going well, "we'd like it to be just as high-performing, and preferably cheaper." That's a huge ask for materials, and I'm not sure they all need to be that. With a lot of materials, we use something that outperforms just because it's cheap enough that it doesn't matter that it outperforms. So, I think performance versus price and expectations, it's a really difficult thing to navigate because the first materials that come out into this space are going to be the lowest performing versions because they’re the first. And they'll keep improving, but we've gotten used to materials that can do almost anything and now we expect it of everything. And we've got all of these startups who are trying to do the type work that used to be the preserve of huge corporations like DuPont, or Dow, or even the military who've got huge resources and budget that can support that. And then you've got tiny startup teams trying to bring materials to market— you've got to get all of the science in place, you've got to scale it up, and you've got to get it to perform. So, I think patience is a difficulty in this space, as well as seeing where the compromises might lie.

EE: That makes sense.

AC: I think the big elephant in the room, and it's something that materials will never solve, and that is consumption—the most sustainable thing that we can do is not buy stuff, but I think we need to find, some sort of substitute for whatever that thrill is or that psychological desire which is fulfilled by buying something new that might only be worn once or perhaps never worn. I think we also need to look at systems and psychology, what else can we do to help that shift? Because it's consumer behavior, which is such a big thing to tackle. And yes, you can make more sustainable materials, but there's no silver bullet for that. Everything has an impact, and you might make something that's got less of an impact, but ultimately it's how people consume that is so much part of the problem. It fascinates me. It's definitely not something that I would know how to tackle, but consumer psychology and how you can maybe make shifts in that I think—if someone could figure that out, that will really make a dent on fast fashion. Or perhaps its different models of fast fashion—can we go to a rental model or a—I don't know. Something that fills that excitement without the impact.

EE: Yeah, definitely. Well, thank you for that. A very important topic. Now a big question. What inspires you today?

AC: I count myself so lucky to work in this field and to have found a job that is also my research obsession. And I am endlessly inspired by companies looking to make things in a new way. I suppose I've talked about nature a lot, but I think it's incredible what nature can build. In that vein there's an amazing company that combines both of those—using how nature builds and rethinking an industry, it’s called Biomason. And they are making something called Biocement. They’re reimagining materials for the construction industry. The production of cement is responsible for eight percent of carbon emissions globally. So, not the sexiest space, but they are growing biocement in the same way that coral grows. They take aggregate, for example waste from the mining industry, and mix that with naturally occurring bacteria, which produce calcium carbonate which locks together all of those grains—in the same way coral builds. There's no firing involved. Their current products are three times stronger than a concrete block. So, it's not just making a bad industry incrementally better, it's just totally rethinking how we make stuff. And it's actually additive—they are adding to global limestone reserves because they are growing it using bacteria.

EE: Really quickly, right? The process is much quicker than coral, right? I think they're super fast.

AC: Yes, it takes just seventy-two hours. It's really something. They're an incredible example of not just, the inspiration of what nature can do and what microorganisms can do, but also totally turning an industry and a traditional way of doing things on its head. I find that kind of thinking and approach inspiring.

EE: Great, thank you. Looking forward, how do you see your practice developing in the years to come?

AC: I would love to continue to explore the role of textiles in tissue engineering, but also just more broadly, thinking about design methodologies or craft methodology and how that can be used in scientific fields. When I first started working in science, I felt like the way I used to sample in a creative studio would be really quite ad hoc. I can be changing fifteen different things in one quote unquote experiment, but then in the lab you have to change one at a time otherwise you have no idea what's having an effect on your results. And to begin with that felt quite constricting, I would think "I want to try and all of these different variables" and all the scientists I work with would be like, "no, no, you need to change one at a time." And that felt like it somewhat stifled creativity, but actually once you understand how to design an experiment, you can be creative quite quickly because you then really get into this systematic of discovery, which is really interesting and that makes you think about your effect on materials in a new way. So, that's all to do with the development understanding methodologies: how to design experiments, and what's the continuing development of the role of a creative practitioner in the field of biotech. Further understanding craft and makers contribution and why that means. I think for me, like I said, whilst I worked in one particular science, I think there's transferable knowledge and skills for all disciplines of science. I just want to see continued knowledge and exploration in that field, and more understanding of "what can textiles bring" because I think it's such an important field of making and has, and can have, such prolific impact in all kinds of industries.

EE: Fantastic. Thank you so much! I'm so delighted that we could speak today.

AC: Thank you for the invite. It's great to be part of this type of project. I mean, I find craft, as a field—and it was part of my thesis actually—an interesting one, and the way it's written about. It's just a fascinating subject for me: makers and the importance of making, and it’s great that it's captured in these kinds of projects. I’m so fascinated by craft and it's conceptual side, and how people view it and how you capture things that are so tactile.

EE: And in your work, I love that the tradition of textiles, as old as it is, is informing these cutting edge, growing into the future technologies that you're working with—and that they're all kind of woven together like that. It's really, really something.

AC: Yeah. It's definitely not what I thought I'd be working on when I first picked textiles. And it's funny when someone says to you, like, what do you do? And I will start with saying something like, "Oh, I'm a designer." And I will have different steps of explaining what I do and thinking "do you really want to know?!" And then I say, "textiles." And the usual response is something like, "Oh, so you make pillows." And sometimes I feel like it’s easier to say "yeah, yeah, that's what I do."

EE: [laughs.] "How much time do you have?"

AC: Yeah, so then I’ll say "I work with organisms and I grow materials," and a lot of people are like, "okay." [laughs.] It's not what they're expecting to hear, but I wouldn't change it. It's been a fantastic, I mean, a fascinating journey and continues to be so, I’m very lucky to be working in the field.

EE: That's awesome. As a student and with my own life history, I commend you so much on being so open to new experience and experimentation, and going where people haven't gone yet. It's really, really impressive to me. So, it's been a delight to hear and very inspiring.

AC: Oh, thank you so much. And thank you for all the wonderful questions. Congratulations on all of the work for the project. It looks incredible, so good luck with the rest of it. I'm looking forward to seeing it all go up. Thank you so much for today.

EE: Thank you so much! It's been an absolute pleasure speaking with you today.

AC: And you. Lovely to meet you, virtually, and have a lovely evening. Get out in the sunshine while it’s still a beautiful day.

EE: Yes, let’s get out there. Bye!

AC: Bye!

[End of interview]

biofabricate.co